The circuit board recycling equipment has injected new power into the environment improvement work

The circuit board recycling equipment has injected new power into the environment improvement work

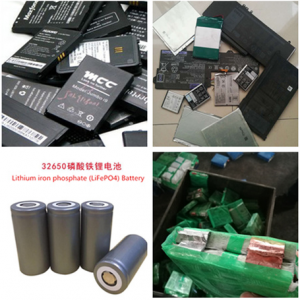

With the social progress and development, waste electrical appliances, mobile phones, televisions, computers, air conditioning, and other electronic products are widely used and rapidly updated, electronic waste is becoming more and more attention to social issues. Electronic waste recycling and processing harmless treatment have become one of China’s environmental protection works. The circuit board recycling equipment mainly deals with all kinds of waste circuit boards, circuit boards, copper-clad boards, scrap materials, aluminum-plastic plates, waste tablets, electronic components, etc., a combined process of crushing-magnetic separation-electrostatic separation is also used to recover metals from waste printed circuit boards (PCBs), which is a difficult problem in Electronic waste recycling.

Some of the equipment will have certain defects

Circuit board recovery equipment most of the technology is mature, belongs to large-scale industrial production, other mostly belongs to small single-machine small batch production. These types of equipment have some defects, such as high energy consumption, low productivity, incomplete separation after grinding, and large fineness range, which make the gravity separation efficiency low and the recovery rate of general metal below 90%. Because of their high production cost, labor intensity, economic efficiency is not ideal, these technologies can not be industrialized production. At present, most of the circuit board recycling equipment is adopted in our country. For the rare or precious metal parts in the circuit board, the method of crushing and separating is adopted, that is, the precious metal is left after the other components are removed. This process does not have “Three wastes”, can guarantee the environmental protection measure, does not have harm the environment and the laborer, and causes these resources to obtain effective use.

Full automatic operation of equipment

Sherlock’s mechanical circuit board recycling equipment to waste circuit boards to 2 mm, and then after magnetic separation method to remove iron, the use of high-voltage electrostatic separation technology for separation, so as to achieve the recycling of resources. For example, the circuit board contains the electronic components, glass, colloid, stainless steel, copper wire, copper, aluminum, rubber, plastic, all kinds of iron can be directly into the equipment for separation and separation, the metal recovery rate can reach 99%. The process from feed to the end of separation, the entire process automation, only 1-2 people to operate. The process is physical dry separation, no heating, burning, water and chemical raw materials, low cost, high efficiency, no pollution at room temperature dry separation. Circuit board recycling equipment in e-waste recycling has established guidelines for the improvement of the environment into a new impetus, the e-waste recycling market will also usher in new vitality.