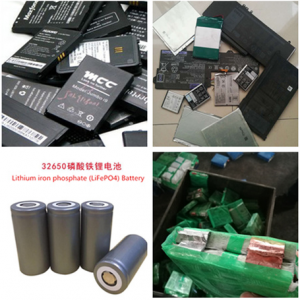

Working principle of lithium battery positive plate crushing recovery production line

Working principle of lithium battery positive plate crushing recovery production line

The lithium battery positive plate crushing recovery production line comprises a feed platform, a pulverizer, an analyzer, a linear screen, a grinding machine, and an induced draft fan, the top of the pulverizer is connected with the analyzer through a pipeline, and the outlet end of the analyzer is connected with the feed end of the linear screen, the outlet end of the grinder is connected with the air inlet end of the induced draft fan 1 through a pipeline, and the outlet end of the induced draft fan 1 is connected with a cyclone collector through a pipeline, the outlet of a cyclone aggregate device is connected with a rotary vibrating screen, the analysis machine, a linear sieve, and a cyclone aggregate device are connected with an aggregate device through a pipeline, and the outlet end of the aggregate device is connected with a dust purification device.

The scrap positive plate of the lithium battery is put into the Shredder for shredding, and then the shredded positive plate is put into the special Shredder for shredding through the belt conveyor. After shredding, the materials are put into the analytical machine for primary sorting, the mixture of metal and polar powder goes into the linear screen for screening, the upper layer of metal aluminum, the lower layer of positive powder, the middle layer of metal aluminum and the mixture of positive powder, the mixture goes into the grinder for grinding, after grinding, the material enters the aggregate and is discharged to the rotary vibrating screen for screening. The dust-containing gas produced in the crushing process is collected by the cyclone and the pulse dust remover.

Waste lithium battery recycling equipment a system can achieve waste lithium battery positive plate recovery, separation of the complete operation, without other equipment, the lithium cobalt powder in the positive plate can be completely separated from the scrap, and the separation purity is high. The separated metal materials: aluminum powder, copper powder and metal nickel can be recovered and reused, the whole system is mainly operated by means of mechanical beating, crushing and other materials. No chemical composition is added in the middle. The operation process is completely environmental-friendly In addition, a grinding machine is installed between the linear screen and the rotary vibrating screen, and the mixture of metal and black powder in the air separator is put into the grinding machine for grinding, and some of the black powder which is curled and entrained with the metal is peeled off.

The lithium battery positive plate crushing recovery production line comprises a feed platform, a crusher, an analyzer, a linear screen, a grinder, a induced draft fan, a induced draft fan and a high-pressure induced draft fan, the feeding position of the feeding platform is higher than that of the Feed Inlet of the pulverizer, and a feeding step ladder is arranged on the feeding platform to facilitate the handling of the positive plate by personnel, and the top of the pulverizer is connected with the analyzer through a pipeline, the discharge end of the analyzer is connected with the feed end of the linear screen, and the linear screen is provided with a discharge port for collecting the metal aluminum, two discharge ports for collecting the mixture and three discharge ports for collecting the positive pole powder, respectively, the second discharge port is connected with a grinder, and the mixture of metal and black powder from the linear sieve is put into the grinder 6 for grinding, and the black powder entrained in the metal is peeled off, thus further improving the separation effect.

The air outlet end of the grinder is connected with the air inlet end of the induced draft fan one through a pipeline, and the air outlet end of the induced draft fan one is connected with a cyclone aggregate, and the material outlet of the cyclone aggregate is connected with a rotary vibrating screen, the material after grinding is sieved through a rotary vibrating screen which is provided with a fourth outlet for collecting metal aluminum and a fifth outlet for collecting positive pole powder respectively, a discharge port and a fourth discharge port are connected with a metal collecting box for collecting metal aluminum, and a third discharge port and a fifth discharge port are connected with a positive powder collecting box for collecting positive pole powder; The analyzer, the straight-line sieve and a cyclone aggregate are connected with a aggregate device for collecting positive pole powder in the airflow through a pipeline, and the outlet end of the aggregate device is connected with a dust purification device, the aggregate device is composed of a second cyclone aggregate and a third cyclone aggregate, and the outlet end of the analyzer is connected with the air inlet of the second cyclone aggregate.